Products

Crimping (Closing) System

Five Advantages Of Products

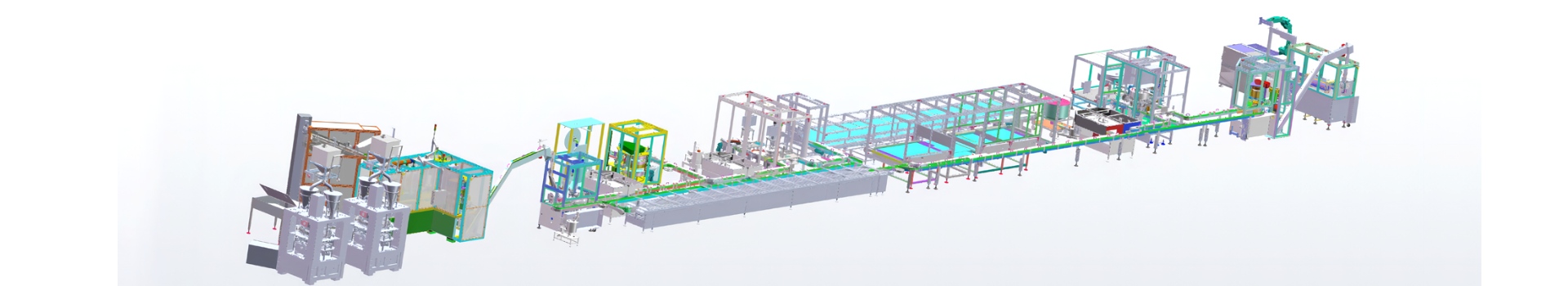

- Automatic & Systemic Alkaline battery assembly equipment

- High Quality process control of battery crimping (closing) system

- High Quality of Equipment parts and assembly

- High Efficiency & High speed @ 600 ppm

- IP Preserved and Design for Customization is optional for best fitting customer's need

Product Details

Working principle:

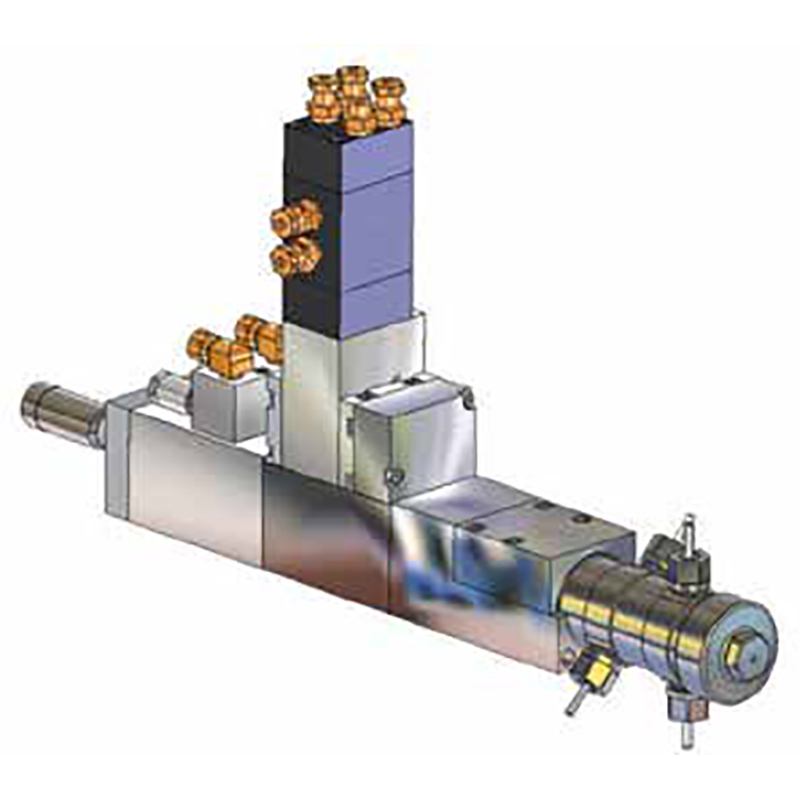

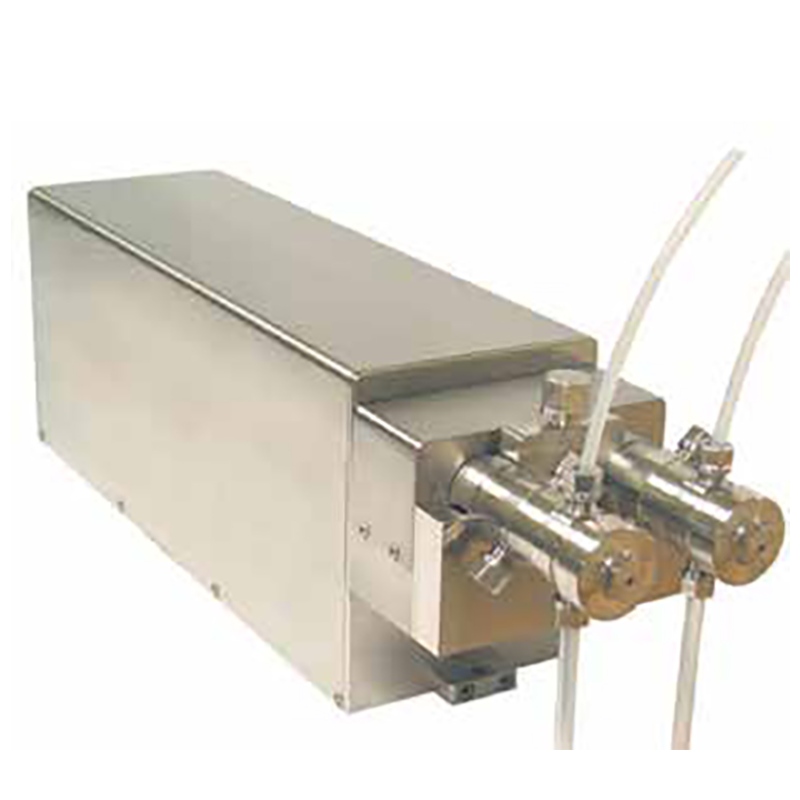

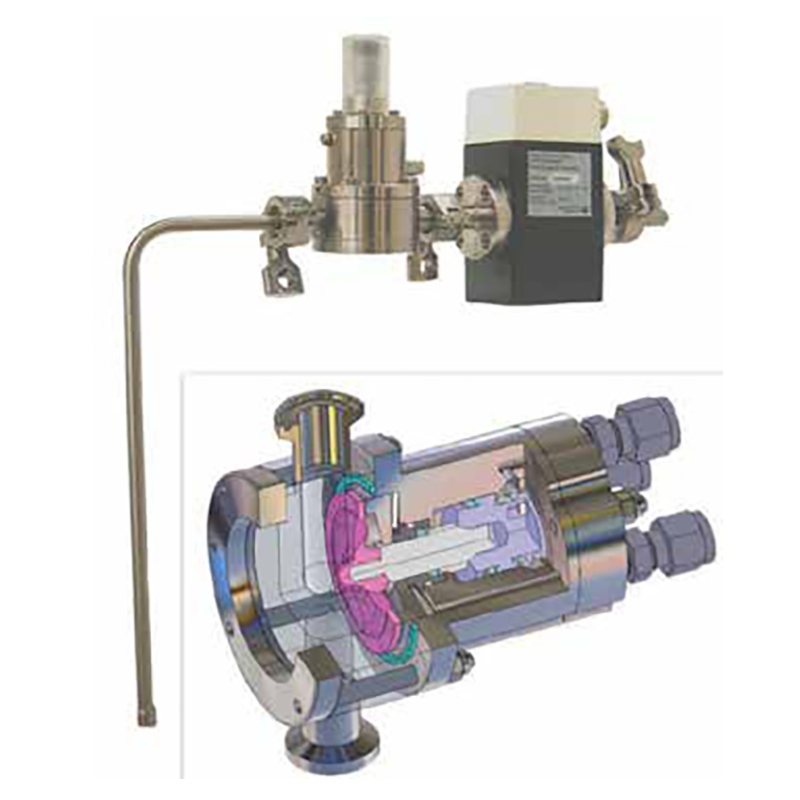

After pre-sealing, the cells are delivered to the unloading wheel, where the empty die is separated into a die sleeve recycling system and the unloaded cells are transported to the sealing sub-station. The cells are sealed by HAVE high performance roller sealing heads, each with three sealing wheels; the cells are clamped by customised grippers and the sealing heads are controlled by cams, with the rotation speed controlled by frequency converters, to seal the cells. After roller sealing the batteries are transported to the mould sealing sub-station where the final shaping and sealing is done by the mould; the shaping and chamfering of the batteries is done by the HAVE mould sealing head.

Equipment characteristics:

Feeding method: die-set cycle transfer system

Inspection method: micrometer, projector, seal testing tooling

Technical specifications:

600 cells/min

DONGGUAN TOPSUN TECHNOLOGY CO.LTD

Contact Person: Lucky Wang

Department: Sales

Post: Manager

Telephone: +86 - 153 2290 2892

Landline: +86 - 134 1212 8547

Company Address: Building D, Tianan Digital City, Nancheng District, Dongguan City, Guangdong Province

Factory Address: Building D, Tian 'an Digital City, Nancheng District, Dongguan City, Guangdong Province

Website: topsundg.us764.com

Previous: Paper Separator Winding System

-

Solar LED Garden Yard Lights Type B series

-

Solar LED Lawn Lights

-

Pneumatic medical PHARMA pumps

-

Medical Sealless Ceramic Plunger Metering Pump

-

MD Series Micro Metering Pumps

-

Diaphragm valve magnetic flux metering series pump

-

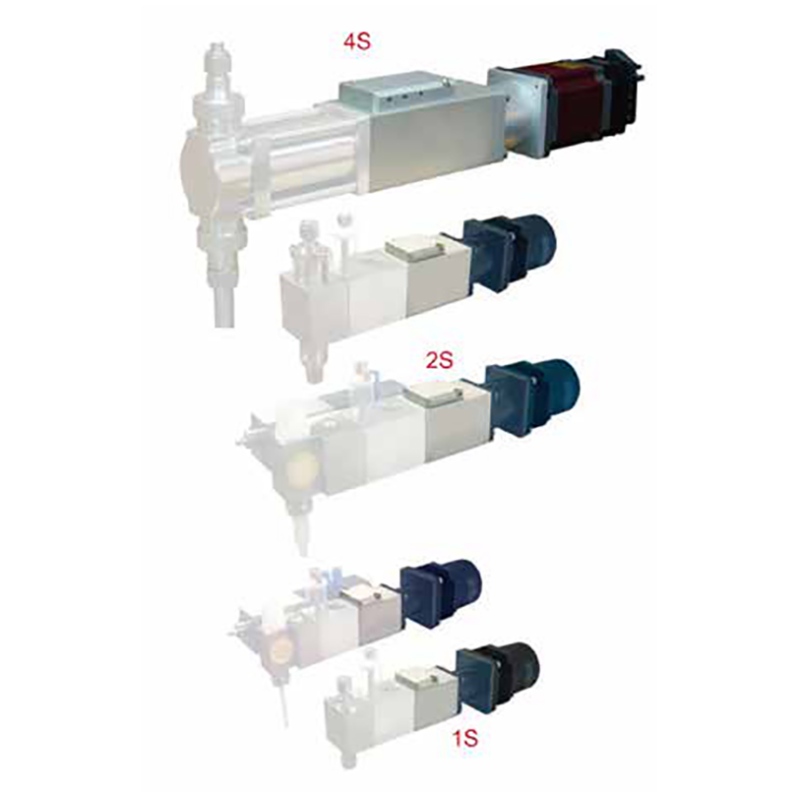

Servo motor driven metering pumps

-

Solar Garden Yard LED Light Type A series